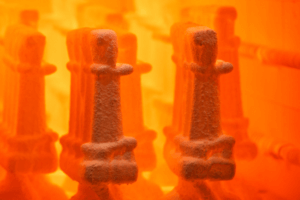

Ferritizing

Ferritizing is mainly used on cast iron workpieces to achieve a soft, ferritic microstructure, which may be desired for further machining, for example.

Rapid cooling of castings can lead to the formation of pearlite, a microstructure mixture of ferrite and cementite. In order to convert the cementite present in the pearlite into ferrite, the workpiece is annealed for a sufficiently long time at a suitable temperature, and slow cooling prevents further conversion into pearlite.

Depending on the composition of the starting material, annealing is carried out in different temperature ranges, e.g. between 700 and 760°C, but sometimes also between 800 and about 1000°C. Especially in the range between 800 and 680°C, it is important that cooling takes place slowly at a rate of about 10 to 20 degrees per hour, which requires a correspondingly programmable temperature control of the kiln.

Of course, KITTEC also offers suitable furnaces and controls for ferritizing. In our product overview you will find, for example, our range of annealing and hardening furnaces. In this context, we would like to refer in particular to our model series CLM and CLU, as well as to our bogie hearth furnaces of the CTH model series. You can also find suitable accessories, such as the hardening table, in our range of products.