Machines & Equipment

Machines & Equipment

Furniture sets, thermocomputers, clay separators, clay presses, spray booths, banding wheels and more… – KITTEC offers comprehensive tools for your individual project with our kilns and furnaces!

Furniture sets, thermocomputers, clay separators, clay presses, spray booths, banding wheels and more… – KITTEC offers comprehensive tools for your individual project with our kilns and furnaces!

Extension rings for Studio-Line CB models

The KITTEC CLASSIC-LINE extension rings bring additional volume and thus more space and flexibility. For a CB 70 S, for example, the extension ring results in approx. 34 l of additional volume and the CB 70 S thus becomes a CB 100 S. The divisibility of these extendible or extended models makes transport through the narrowest of door openings possible (from door width of 50 cm). The extension rings are currently available for the following CLASSIC-LINE kilns: CB 70 S, CB 80 S, CB 95 S, CB 130 S plus, CB 130 SX, CB 200 S, SQ 90 S, SQ 150 S.

A large selection of support materials for your perfect firing.

KITTEC offers various support and stacking materials, tailor-made for our pottery and ceramics kilns, guaranteed to make work easier for you. Our furniture sets include high quality burning plates in various shapes and sizes, as well as the necessary support elements. You can use the sets to place your pieces on different layers, allowing you to burn several pieces at once. The burning plates are made from high quality heat-resistant material, able to withstand the extreme temperatures during burning. To figure out the matching furniture set for your kiln, feel free to contact us for assistance!

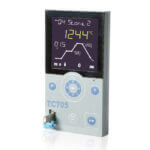

Versatile control options – the KITTEC Thermocomputers.

High quality control systems, extremely easy to use: depending on the model, KITTEC Thermocomputers offer programmable firing curves for every application, from simple four-segment curves sufficient for regular pottery and ceramics (lead time, controlled heating at two different intensities, hold time, controlled cooling), all the way to freely programmable firing curves suitable for the most elaborate applications like glass processing.

KITTEC clay presses are based on a simple, but very sophisticated technology, with which potters can make clay strands for their creations.

The container for the clay mass can be filled with a whole 12.5 kg of blank clay. By a slight, downward movement of the ratchet lever, the clay is pressed through an individually selected template on the bottom of the container. Depending on the shape of the template, hollow round, rectangular or octagonal clay strands are produced. The KITTEC Clay Press TP can be mounted on sturdy concrete, wood or brick walls. As an option, however, we also offer a special frame, which only has to be fixed to the floor.

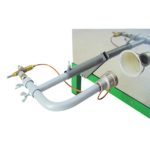

Clay separators, also called glaze and clay separators, are used to keep glazes, clays and engobe remains out of the sewer system.

For this purpose, the KITTEC clay separator is installed under the sink. The settable substances in the waste-water are separated by the simple but highly effective three- chamber system at the bottom of the clay separator. This prevents pipe clogging and protects the environment, so compliance with the waste-water regulations is no longer a problem.

Clay that has been stored correctly remains malleable for longer

The clay container consists of hard-wearing plastic with a smooth inner wall and recessed handles. A suitable trolley is optionally available for each type of clay container. The almost hermetically sealed lid makes proper storage of the clay possible.

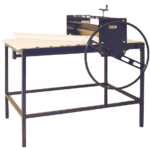

Robust professional devices for consistent slab properties.

KITTEC slab rollers have been designed for many years of use in workshop and industrial operation. The rack and pinion drive of the RM 1 meshes seamlessly and smoothly when transferring power. Centrally via only one adjusting wheel, you can adjust the height precisely using the measuring scale, giving you best results in just a few steps. The KITTEC RM 1 slab roller can be used both as a stand-alone unit and as a table device. The KITTEC CreaP slab roller works on existing tables or working tops while saving precious workshop space when stowed away after use.

KITTEC spray booths ensure a dust- and aerosol-free work environment in the workshop when spraying glazes or ceramic paints.

The booths have a fully enclosed working area which is only open at the front. Negative pressure in the booth is generated via a suction fan so that fine glaze or paint particles cannot escape from the spray booth. The KITTEC SB 1 spray booth is ideal for smaller workshops and can also be used as a convection model: the sucked-in air is filtered and returned to the room after cleaning. The robust and durable metal filter has several filter inserts offset to one another. At the rear, the cleaned air is returned to the workshop. To clean the galvanised metal filter, it is simply pulled out of its guide, then cleaned under running water. The KITTEC SB 1 spray booth can be placed on a table or can be used on the supplied legs. It is made of solid steel and is delivered ready for connection. A banding wheel for the placement and movement of work-pieces in the KITTEC SB.

Hardening table with various extension options available.

KITTEC Hardening tables are stable tables, with a depositing shelf for tools etc. below the work surface. Quenching tanks can be mounted on both sides, stainless steel for water and regular steel with a hinged lid for oil. Additional extension options include a fan set for forced cooling, thermostat-controlled heating elements for both table and quenching tanks and heat-reflecting bricks for the cooling grate, allowing the table to be configured as a combination table, to be used for heating up (for forging, welding, flame hardening etc.) or as a slow cooling chamber.

KITTEC banding wheels are the ideal aid for painting and banding of ceramics.

Due to their precise bearings, the banding wheels prove to be outstanding, with long, quiet and smooth running. The centering grooves allow precise alignment of the objects and thus exact work. With our different versions, we have the right solution for every application.

Everything needed for successful Raku firing

Raku – a firing technique from the far east. Each piece of ceramic produced by this process is unique, unmistakable and not reproducible. Every ceramist is free to develop their own technique, giving their pieces a distinctive style. This always makes Raku exciting. KITTEC not only offers easy-to-use, easy-to-handle Raku front and top loaders with very short heating up times, but also a comprehensive array of tools for Raku firing, like Raku gloves and tongs, as well as a variety of self construction materials which you can use to build your own Raku setup, like dedicated Raku or pot burners, thermocouples and bottle connections.