![]()

PROFESSIONAL-LINE XG gas front-loader, up to 1,320°C

Gas technology – simple and safe

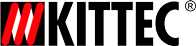

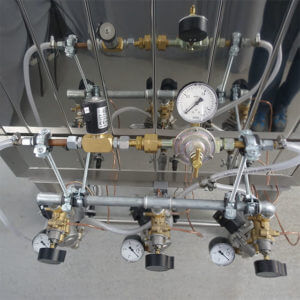

The XG model series provides optimum temperature distribution thanks to the downdraught flame control. As well as being independent of electrical connections, the possibility of firing under a reduction atmosphere is a particularly strong argument in favour of using gas kilns. However, this reduction firing requires a certain amount of firing experience, since reduction firing is not easy to reproduce. Each item that is fired is slightly different – and therefore unique.

The KITTEC gas kilns are equipped with burners for propane/butane as standard. However, we can also offer natural gas heating systems.

One of the outstanding quality characteristics of the KITTEC gas kilns is the so-called downdraught flame control, which provides absolutely even temperature distribution in the entire kiln. The best prerequisites for gas kiln professionals.

Features of models series XG:

![]() Housing and frame made from stainless steel

Housing and frame made from stainless steel

![]() Pairs of legs with adjustable height (except XG 1000)

Pairs of legs with adjustable height (except XG 1000)

![]() Adjustable door lock

Adjustable door lock

![]() Very well controllable high-performance burner for propane/butane (extremely quiet)

Very well controllable high-performance burner for propane/butane (extremely quiet)

![]() Down draught flame control

Down draught flame control

![]() Stainless steel exhaust hood

Stainless steel exhaust hood

Further features of model series XG:

- ESP Energy Saving Package: High-quality and innovative multi-layer premium insulation makes fast heating-up possible, even in the upper temperature range.

- Manually controllable damper

- Stable SiC ceiling plate, no contamination from above

- Includes CO alarm

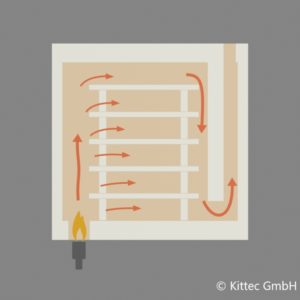

- Pressure regulator with manometer (including all fittings between burner and gas supply), simple and safe gas technology in accordance with the DVGW

- Temperature indicator (battery-powered)

- Continuous mortar-free brick lining reduces cracking

- Housing and frame made from rust-proof stainless steel

- Extremely solid lightweight refractory brick ASTM 26 in regions with considerable mechanical stress

- Wide door opening angle for easy loading (approx. 150°)

- Stainless steel exhaust hood in the centre at the rear

(with flue connection ø 150–200 mm) - Thermocouple for temperature measurement, installed with protection

- Base with cross strut for easy transportation using a lift truck

- Customised products by request

Optionally available:

![]() Natural gas burner

Natural gas burner

![]() Inspection hole (including bung)

Inspection hole (including bung)

![]() Loading rack

Loading rack

Further options of model series XG:

- 230 V mains adapter for temperature indicator

- Oxygen probe for atmosphere measurement

- Levelling feet for compensating for floor unevenness

- 2-bottle adapter

- Left door hinge

- Propane or natural gas firing curve management incl. TC 66 controller, semi-automatic, makes individually adjustable automatic firing curves possible (but no automatic oxygen content control)

- Increased maximum temperature 1,350°C or 1,400°C

Bricks and insulation designed for 1,350°C and 1,400°C

KITTEC PROFESSIONAL-LINE, model series XG:

All data subject to technical change without notice.

Appropriate firing sets, tools and additional equipment to KITTEC PROFESSIONAL-LINE kilns are available here. Should you have questions about this model series or wish to get more information or customized advice, please feel free to contact us. We will get back to you shortly.