Solution annealing

When machining austenitic, non-rusting steels, undesirable changes in the material structure can occur, which can negatively alter the material properties.

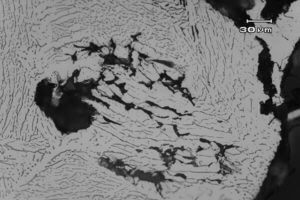

Steels with certain alloy compositions are called austenitic steels because they form a so-called austenitic structure during (slow) cooling from the melt, which results in certain material properties, such as high corrosion resistance, very high toughness and good weldability.

However, if cooling takes place too quickly, certain alloys may form undesirable crystals of other phases (e.g. ferrite) which do not dissolve again.

For example, when welding some austenitic steels, the cooling of the welded areas takes place so quickly that the ferritic crystals that have formed in the meantime do not have enough time to transform back into an austenitic structure. In these areas, the workpiece then has different properties, for example in terms of toughness or corrosion resistance.

Solution annealing counteracts this. In this process, the workpiece is specifically brought to a suitable temperature (for steels approximately between 1020 and 1080° C) at which its mechanical strength is retained but the crystal structure can transform back into an austenitic structure. This temperature is maintained long enough for the undesirable ferritic crystals to dissolve and transform into austenitic ones.